The Signature Principle

Value creation through responsibility

With our Protec Blu Signature® initiative, we want to further advance the ecologically necessary transition from a linear economy to a circular economy and to harmonize ecological thinking with economic action.

For us at Protec, sustainability is not a trend or something new - it is an integral part of our selfimage.

The Protec Blu Signature® initiative must be seen as an indicator that at Protec, we avoid environmental pollution and assume responsibility for our environment, at all times and in all processes. We have optimized our production processes to protect the soil, air and water. A responsible approach to our environment is at the heart of our corporate philosophy.

As a plastics processing company, we are committed to making our products and processes as environmentally conscious as possible. For this reason, of course, our production facilities are DIN EN ISO 14001:2015 certified.

Based on our concepts of sustainability, we use natural resources so sparingly and efficiently that their use in the production of our products reflects the harmony between economy and ecology, and therefore, responsible action in this society.

This is only possible because our Protec Blu Signature® initiative achieves a harmonious balance between environmental protection, economic efficiency and sustainability, from which additional added value is created through sustainability and responsibility, and because we harmonize economic, ecological and social goals.

A further key to increasing environmental protection and sustainability begins with the qualification and training of our employees and extends far beyond improving the energy efficiency of our exhaust air and waste water systems. We consider the sustainable care of our environment to be our duty - a duty which we are happy to fulfill.

At Protec, we also constantly optimize our environmental processes and develop measures to achieve specific goals, which we also regularly revise and update. It also goes without saying that we comply with all legal regulations and official requirements for environmental protection and the conservation of energy.

Our PROTEC BLU SIGNATURE® initiative ensures that the necessary resources are always available for putting our principles into action and it also checks their effectiveness and suitability annually.

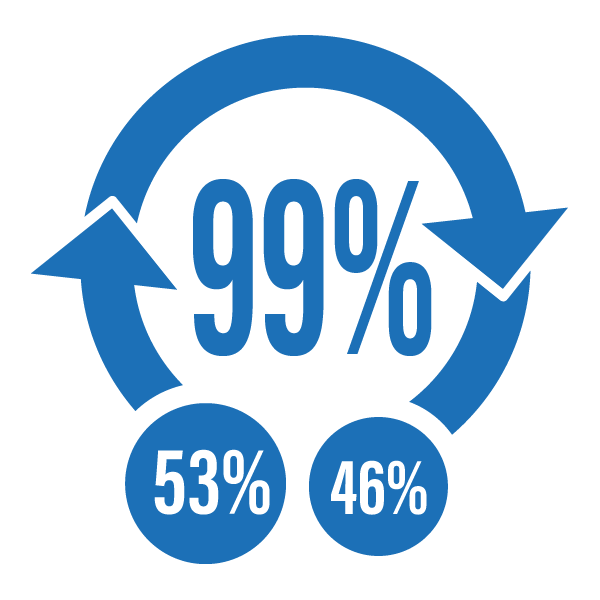

All Protec products are used exclusively in the B2B industrial sector and are therefore subject to a strict chain of controls during the production and processing stages. These controls range from the initial recycling of the raw material, its application, a second recycling of the product as a plastic recyclate, to the proper disposal of the end product.

More than 99% of the plastic waste generated in the B2B sector is recycled, of which approximately 46% is recycled as material and approximately 53% is recycled as energy. Plastics recycling has established itself as an essential component and economic factor in the plastics industry.

In addition, through our own research and development, alternative materials are tested as part of our PROTEC SIGNATURE initiatives, which meet the demanding requirements of industrial users and cause as little damage as possible to the environment, both during production and disposal.